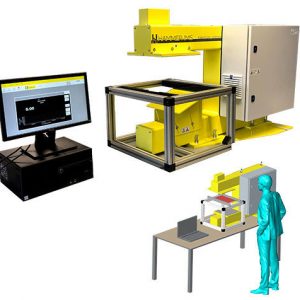

CURTAIN system for inline thickness and basis-weight measurements

Turn-key CURTAIN machines integrate the M-Ray measurement technology for industrial use. The machines are tailored to perform measurements 24/7 as part of an industrial production line. Every CURTAIN O-frame and C-frame contains one or more M-Ray based measuring heads. These sensor heads measure the basis-weight, thickness or anomalies in various flat semi-finished products. Thanks to the nature of the M-Ray technology, the measurement standoff can be as high as 30 centimeters. The high standoff is useful for measuring thick materials and avoids scratches and defects on the material.

Instead of M-Ray based Marveloc sensor heads, Hammer-IMS allows for integrating other sensor types (see Sensor Fusion page) into a traveling or fixed CURTAIN system.

CURTAIN C-frame – Offering arm length up to 1.5 meter

The CURTAIN C-frame system, displayed on the right, uses a 100% classic scanning C-frame concept. Its design is sleek and slim. The system can be equipped with one or more measuring heads. The system brings the power of multi-head to classic C-frame measuring technology. The pure electronic nature of the M-Ray technology within this fixed or scanning frame is non-nuclear and non-radioactive. The M-Rays’ high dynamics allow for high-standoff measurements that are fast and accurate. C-frame CURTAIN systems are available with arm lengths up to 1.5 meter. Such systems are extremely flexible because they can simply be inserted on either side of a production line without interrupting production. C-frame type systems can be used on lines of any material width.

Measured physical value : weight, thickness

Other characteristics : multi-sensor, multi-sensor

Reviews

There are no reviews yet.