Genius WEEE (Waste Electrical and Electronic Equipment) processing plant is a set of machines connected the one to the other and logically coordinated by a dedicated software: Its processing capacity is 1000 – 1500 Kg/h. There are 5 main machines which can be arranged according to the customer’s needs.

The process starts with the preparation of WEEE for shredding. The materials which are potentially dangerous for the shredder’s blade must be manually removed by the operator. The tempered WEEE material is then loaded on the loading conveyor belt which unloads the material into the loading hopper.

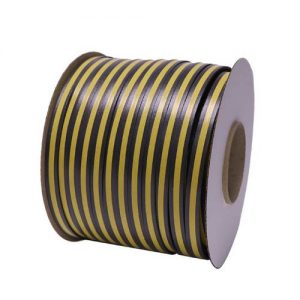

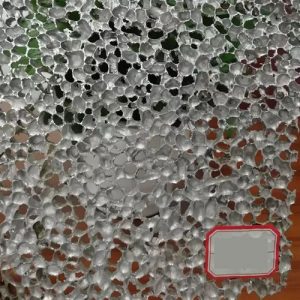

The material is then shredded by means of a two shaft or four shaft shredder ; the power can be varied on request. The material comes out from the shredder with a particle size of about 30 mm and is extracted through a belt placed next to a magnetic separator which sorts the ferrous material and unloads it on the machine side where it can be put into a container. The debris passes then through a machine which uses induced currents to sort non-ferrous metals by unloading them elsewhere. A suction plant is also provided to avoid dusts which could pollute the sorted material.

This WEEE processing plant allows to sort the following: ferrous metals, non-ferrous metals, plastics, printed circuit boards, electric transformers, small engines, electrical wires, batteries, condensers and mixed waste.

A special configuration is provided for the processing of fridges, washing machines and dishwashers by means of a shredder with crushing blades.

Options : waste

Reviews

There are no reviews yet.