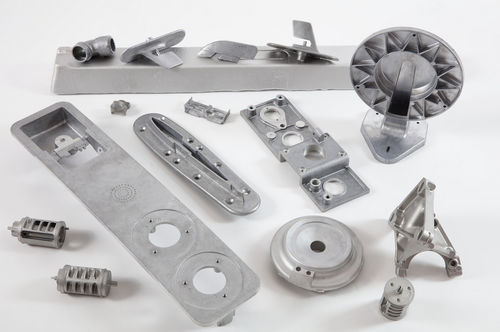

– High pressure die casting consist in injecting, under high pressure, a molten alloy in a metallic mold that solidifies quickly to form a workpiece.

– This transformation process allows to reproduce complex pieces with thin walls.

– It’s a fabrication process economic and fast for the production in large production of light alloy parts.

– One of these main advantages is to have a high repeatability and a high tool life.

Characteristics of the aluminum used in high pressure die casting

– At equal volume, aluminum has 34% by weight of steel

– Aluminum is an excellent conductor of temperature, 1.8 times better than copper

– Die-cast aluminum has good rigidity and good strength / weight ratio

– It also offers the possibility of high working temperatures

– Recycling aluminum is easy and economical, environmentally friendly

Material : titanium, steel, copper, zamak, aluminum, brass, bronze

Production method : large series, medium series, small series

Applications : for aeronautics, automotive, medical, for the construction industry, for the food industry, for railway, for the energy sector, for transportation

Certifications : ISO 9001

Reviews

There are no reviews yet.