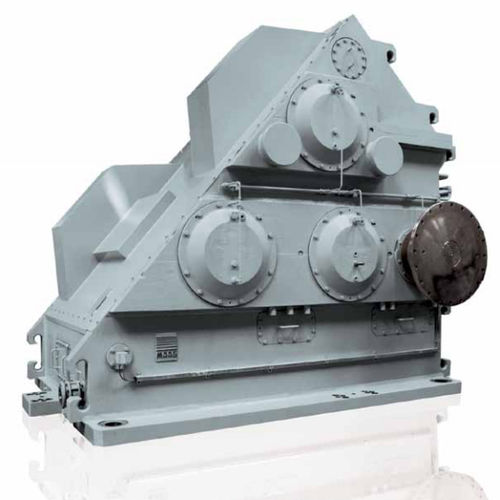

The success of the MAAG lateral mill gear drive is based on its design. It is positioned 40° under the mill which demands a compact type of construction and leads to lesser building and foundation costs as a lot of space is saved.

Further advantages of the LGD are as follows:

– Integrated oil system

– Direct lube oil return from the girth gear to the integrated lube oil tank prevents contamination of oil

– Minimum oil flow in the girth gear guard

– A tooth safety factor of at least 2,3 (AGMA)

– Calculated bearing service life of 80’000 hrs

One of the major benefits of the MAAG LGD drive system is the torque split between the two pinions. It ensures that the total torque to the mill is always equally distributed from both pinions. Any deviations in torque between the two pinions is automatically equalised by axial adjustment of the intermediate shaft triggered by the deviations in the axial forces. A crowned toothing between the pinion and the pinion shaft enables the pinions to self align. This ensures full tooth contact even at a smaller run out of the girth gear and compensates pitch errors.

Type : spur

Shaft orientation : parallel-shaft

Number of stages : three-stage

Other characteristics : compact

Reviews

There are no reviews yet.