Poor quality plant service water and temperature variation can cause major problems with sample cooling. Plant service water chemical and physical purity, pressure and temperature are of particular importance for proper sample cooling. If the water contains any hardness, exposure to high temperatures in the sample coolers can result in scaling and a loss of cooling efficiency.

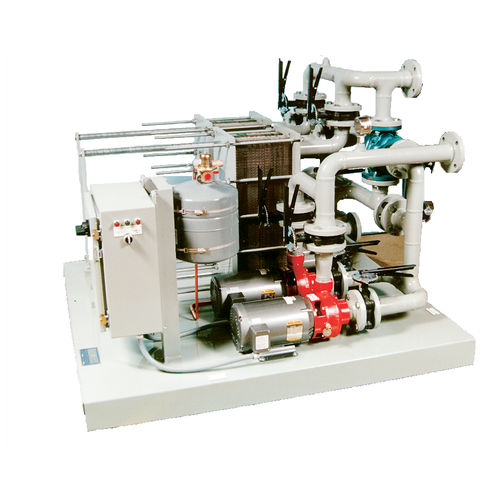

Chemical contaminants such as chlorides can cause stress corrosion cracking of stainless steel at elevated temperatures. Undissolved material in the water (e.g. silt, organic matter and corrosion products) can plug the sample cooler minimizing heat transfer capacity. The flow of cooling water may be insufficient due to low source pressure or excess pressure drop in the supply piping. Seasonal temperature variation of plant service water also affects sample temperature stability and analyzer readings. A Sentry CWIS cooling water isolation skid can solve these issues.

Benefits

Eliminate problems associated with high silt, hardness, chlorides, and micro-biological aquatic life by isolating a closed cooling loop to your sample coolers or other equipment

Maximize sample cooler efficiency and life

Packaged system with numerous sizes and options including redundant heat exchangers or pumps

Type : sample cooling water

Reviews

There are no reviews yet.