Biogas compression and treatment system composed of an oil-injected rotary screw gas compressor, directly coupled to an electric motor through a flexible coupling, controlled by inverter and by pass.

The regulator system could be customized to follow customer needs.

Typically used for biogas upgrading.

UVG160-10ED-INV (OF)

Biogas compressors for a biomethanization plant by PSA in China

Suitable for ATEX zone 2, open

frame for indoor installation, complete with gas treatment system for

oil removal

SPECIFICATIONS:

Power: 200kW (de-rated)

Inlet pressure: 60 – 100mbar(g)

Outlet pressure: 10bar(g)

Ambient temperature: 3°/40°C

Capacity: 0<370<966Nm3/h

UVG90-14.5MD-INV (OF)

Biogas compressors for a biomethanization plant by membranes in Austria.

Designed for classified Atex

zone1, completely water cooled,

open frame for indoor installation.

SPECIFICATIONS:

Power: 90kW

Inlet pressure: 50-150mbar(g)

Outlet pressure: 14.5bar(g)

Ambient temperature: 3°/40°C

Capacity: 0<310<550Nm3/h

UVG250-15ND-INV (OF)

Biogas compressors for biomethane plant in combination

with a biogas upgrading system

through membranes in UK. Designed for classified ATEX zone2,

open-frame on skid mounted into

a container, complete with gas

treatment system for oil removal.

SPECIFICATIONS:

Power: 315kW (de-rated)

Inlet pressure: 27<200mbar(g)

Outlet pressure: 15bar(g)

Capacity: 0<920<1491Nm3/h

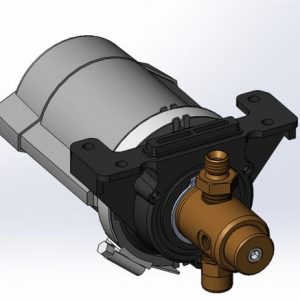

The lubricated single-stage oil-injected rotary screw compressor is composed of two rotors: a 5-lobe male and a 6-slot female one with asymmetrical profiles. Rotation of the rotors pro-duces compression of the gas with continuity and without pulsations.

Technology : rotary

Type : biogas

Power source : electrically-powered

Portability : stationary

Lubrication : oil-injected

Application domain : industrial

Other characteristics : direct-drive, single-stage, water-cooled, inverter

Pressure : Min.:

Flow : Min.:

Power : Min.:

Reviews

There are no reviews yet.