Mechanical protection for optical fibers

While optical fibers are fairly durable, they often cannot withstand all possible environmental conditions – especially those in harsh industrial surroundings. This is where additional protection becomes necessary, which prevents the fibers from being damaged or coming into contact with substances that could adversely affect their transmission performance or longevity. Protective tubes are available for various optical fiber assemblies, to protect against damage from longitudinal and transverse forces, and various environmental factors. Plastic tubes and reinforced tubes are used for the direct assembly of multi-fiber loose tube cables with fanout elements for mechanical protection of the fibers. To ensure proper handling of cables during installation and maintenance work, the application of warning marks is very helpful and easily achieved.

Appropriate protection for almost any optical assembly requirement

Against damage from longitudinal and transverse forces

Against various environmental factors: flame-retardant, rodent protection, limiting the bending radius, vacuum-compatible, high-/low-temperature resistant, with strain relief, non-crushable, and many more

For proper handling during installation and maintenance work (e.g. colored markings and warning notices)

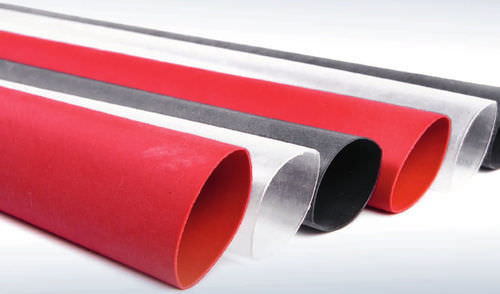

Protective tubes

Plastic

Metal

Metal/plastic

Metal/silicone

Fabric

Plastic tubes and reinforced tubes for cable dividers

Maximum assembly length: 200 m (depends on fiber, tube, and cable type)

Available only as an assembly option, not available separately

Depends on material

Flame-retardant

Media resistance (oil, water, acids, bases, etc.)

Type : protection

Structure : tubular

Applications : for fiber optic cables

Material : fabric, plastic, metal

Protection level : halogen-free, abrasion-resistant, acid-resistant, oil-resistant, flame-retardant, water-resistant, reinforced, for harsh environments

Other characteristics : high-temperature, low-temperature

Reviews

There are no reviews yet.