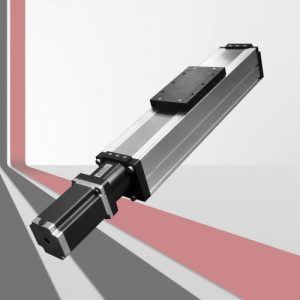

Quattro power due to four-planet system. Highly rigid drive unit made up of an input multistage right-angle gear unit and a robust planetary output stage. Flange output shaft. Synchronous servo motor EZ. Extremely compact. Highest power per unit volume. Large torque. High dynamic.

Shaft designs

– Flange shaft

Output available on side 3 or 4.

Output Side

Bearing Design

Pretensioned angular contact bearings at the output in an O-arrangement, ideally suited for helical geared rack and pinion drive.

Mounting Positions

– Any mounting position.

– You can find the explanation of the mounting positions and the respective quantities of lubricant in the document Quantity of lubricant for gear units ID 441871

Lubricants and Maintenance

– Synthetic lubricant CLP HC ISO VG 150

– Lubricated for life

– Maintenance-free

Paint Finish

– Housing and connector black RAL 9005

– Motor cover b-side magenta RAL 4010

Synchronous Servo Motor EZ

– Extremely compact.

– Highest power per unit volume.

– Large torque.

– High dynamic.

Synchronous Servo Motor EZ

External Fan

– According to DIN EN 60034-6, IC416

– To increase torque and continuous performance.

– In case of higher surrounding temperatures.

– Also available as a retrofit kit.

External Fan

Motor Brake

Optionally the motor b-side can be equipped with a permanent magnet holding brake.

EZ Brake

Encoder

Motor type : permanent magnet, synchronous

Type : planetary, helical

Shaft orientation : right angle

Power : 1 kW…2 kW, 2 kW…5 kW, 5 kW…10 kW, 10 kW…20 kW

Torque : 20 – 50 Nm, 1 – 5 Nm, > 10 kNm, 0 – 0.1 Nm, 5 – 10 Nm, 50 – 100 Nm, 100 – 200 Nm, 500 – 1000 Nm, 5 – 10 kNm, 10 – 20 Nm, 200 – 500 Nm, 0.5 – 1 Nm, 0.1 – 0.2 Nm, 1 – 2 kNm, 0.2 – 0.5 Nm, 2 – 5 kNm

Product applications : for heavy-duty applications, with encoder

Other characteristics : compact

Reviews

There are no reviews yet.