In generation grinding some of the changes to be made are applied to the wheel and part to the grinding cycle.

With an interpolation of multiple axes between the dressing tool and the grinding wheel during dressing double ank, the desired prole of the grinding wheel screw is generated point by point creating any type of desired prole without the use of a dedicated roller. The “disadvantages” of this type of cycle consist in a considerable lengthening of the time of startup production and of the dressing cycle, compared to the standard dressing.

The advantages can be seen by comparing this type of processing with a processing performed with the grinding wheel shape, while lengthening the time of dressing, it allows a shorter processing time, also decreasing the risk of burns and production times.

“Rettiche Resca” is currently the only company in this branch to oer this technology as a contractor with reliable results.

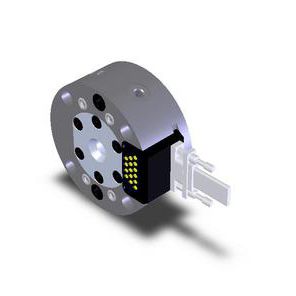

Here below you can see an example of proles obtained with this technology with an excellent ratio between quality and processing times.

Type : internal cylindrical

Treated material : steel

Applications : automotive

Certifications : ISO 9001

Production method : large series

Reviews

There are no reviews yet.