Application

Fish defroster is designed for frozen fish block or IQF product defrosting in water. Water defrosting minimises weight loss in defrosting operation.

Water defrosting is used when high capacity defrosting process is needed.

Main benefits

Easy fish loading – it is possible to load fish with crates and remove creates afterwards

Easy cleaning – due to hydraulic lift

Ergonomic operation

Operating principle

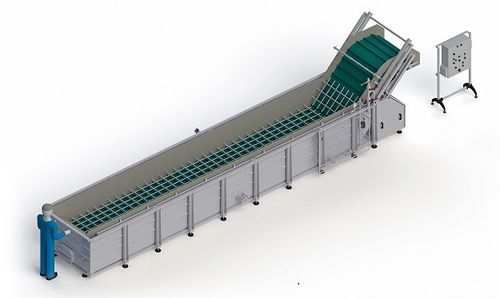

Frozen fish blocks are manually loaded in defroster in its whole length. If fish is blastfreezed in boxes, fish together with boxes can be put into water. Boxes then are removed when fish is separated form box surface.

Frozen fish block are defrosted in warm water and air flow. Defrosted fish separates from the block and fellls onto conveyor belt which transports it out of the defroster to the next technological unit.

Water temperature and water level is regulated automatically with the help of PLC.

For device operation customer must provide electricity, water, hot steam and drainage.

Processing capacity

Raw material defrosting capacity

Single water defrosting lineUp to 1200 kg/h

Double water defrosting lineUp to 2400 kg/h

Technical characteristics

Performance Up to 2400 kg/h for double defrosting line

Defrosting ambience Warm water, forced water circulation, forced air flow

Fish infeed Manual

Water heating source With steam

Equipment dimension (LxWxH) – Double line 9600 x 4400 x 2300 mm

Equipment dimension (LxWxH) – Single line 9600 x 1800 x 2300 mm

Number of operators 1 for each defrosting line

Electrical power 3,5 kW for each defrosting line

Type : immersion

Food product : for fish

Batch/continuous : in-line

Applications : for the food industry

Reviews

There are no reviews yet.