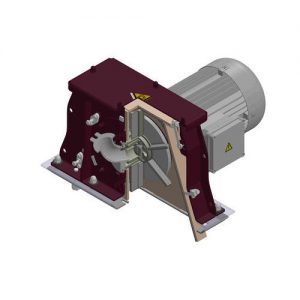

These steel gear hub / nylon drive sleeve gear couplings are designed to release neighbouring shaft bearings from non-controlled additional bearing loads.

Maximum shaft diameters of 100 mm can be accommodated with maximum torques up to 2,400 Nm and speeds up to 8,000 rpm.

Single or double engagement options suit a variety of applications.

Continuous sleeve or flanged connections for high power drives.

Vari-Crown tooth form has higher tooth strength when misaligned.

Available for either horizontal or vertical installations.

Disengaging or shear pin options on request.

Spacer type connections accommodate large shaft end gaps.

Nylon sleeve options require no lubrication.

Further information and technical specification catalogue found at https://www.jbj.co.uk/gear-couplings.html

Type : gear, torsionally rigid

Product applications : for pumps, for shafts, for wind turbines, for railway applications, for servo motors, for machine tools, for railway vehicles, for printing machines, transmission, industrial, for marine applications, for mechanical power transmission, for rolling mills, for conveyors, for mixers, for agitators, for diesel engines, for the food industry, for electric motors, for the packaging industry, for lifting equipment, for the textile industry, for paper machines, for bearings, for gears, for the cement industry

Other characteristics : shaft-hub, misalignment correction, compensating, high-performance, anti-vibration, flywheel, non-lubricated, low noise and vibration, with spacer, disassemblable

Installation system : sleeve

Torque : Min.:

Rotational speed : Min.:

Reviews

There are no reviews yet.