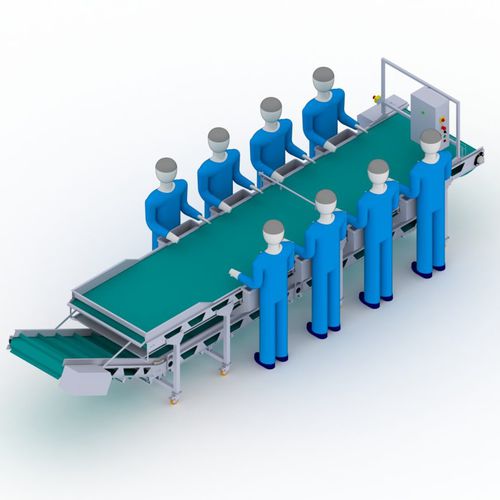

Manual grading line

Application

Manual grading line is developed to sort out more valuable fish species in the production process.

Manual grading line comes in various executions and lengths. Avaliable options for 5 till 24 operators.

Manual grading line can be eqquiped with platforms for opperators, which minimises contact area with the floor.

Main benefits

Ergonomic design

Adjustable working positions

Sanitary and easy cleanable design

Stainless steel construction.

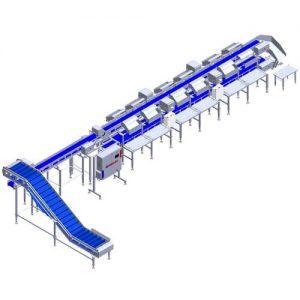

Operating principle

Fish is supplied to the infeeding hopper. Fish can be supplied by forklift or by choosing PERUZA tipper for containers.

Further fish is passed onto grading conveyor. Conveyor brings fish closer to operators for inspection. Operators carry on visual inspection for fish passing by on grading line and grades

out previously specified fish. Fish can be graded out by species, size or other properties.

After grading, each grade is conveyed to separate bin for further processing.

Grading properties can be switched immediately as the grading process is done by employees.

Manual grading line

Product Any product that must be sorted

Number of operators 5-25

Number of grades Up to 3

Grading capacity 1000 kg – 10000 kg

Technical characteristics

Performance 1000 – 10000 kg/h

Fish infeed Hopper elevator or fish grader outfeed

Material AISI 304 (AISI 316 option)

Number of operators 5 – 24

Applications : for fish

Reviews

There are no reviews yet.