For open die forging processes like cogging, becking, mandrel drawing, the numerous part movements can easily be defined and validated, reheat can be predicted and equipment dimensioning can be set. With FORGE® NxT, all the movements of the part imposed by the manipulators, displacements and rotations, can easily be setup thanks to a Multi Pass File, and the simulation of all the blows is handled in a unique launch.

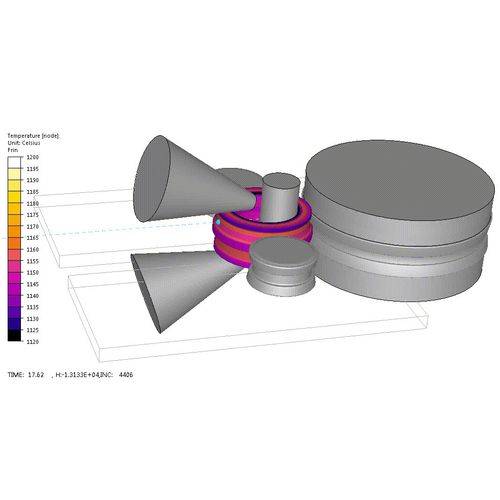

For ring rolling processes, refined piloting reflecting the actual ring rolling mill ensures accurate simulation. Movements of the cones can be taken into account as well as centering rolls.

With embedded heat treatment capacity, FORGE® NxT allows to simulate the complete process workflow up to quenching in order to predict the hardness, the metallurgic changes, the distortions, residual stresses. Various quenching conditions can be reflected:

Non homogeneous HTC,

Descent into the bath,

Spray quenching

Quenching model support both TTT and CCT curves.

Functions : energy management, simulation, measurement, quality, embedded

Applications : process

Reviews

There are no reviews yet.