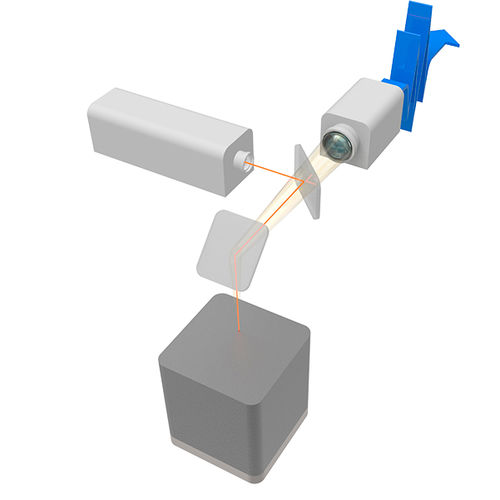

QM Meltpool 3D involves meltpool monitoring that detects the crucial stage in the LaserCUSING® process with a photodiode and a camera.

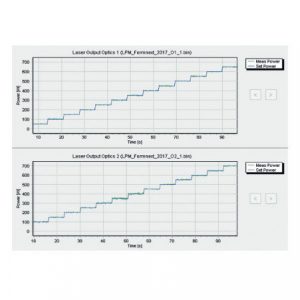

The photodiode records the meltpool emissions that are produced during the melting process in the infrared range. With an observation area of 4 cm2 , the photodiode shows the irregularities in the melting process and thus determines the meltpool intensity. The camera detects areas of 1 mm2 and allows a detailed view of the meltpool area. This feature is particularly crucial for ascertaining the quality of the part.

The data from QM Meltpool 3D is available immediately after the build process. Using software that is also used in computed tomography, it is now possible to generate a 3-dimensional or 2-dimensional image of the part. This means it is possible to analyze the component in automated fashion with the aid of software. The coaxially arranged detectors of the camera and photodiode enable a high resolution of 35 µm. This was recognized with the International Additive Manufacturing Award 2016.

QM Meltpool 3D is used primarily in industries with high quality requirements such as the medical or aviation industries. The in-situ real-time process monitoring system allows downstream process controls to be minimized.

Applications : for DMLS, for melt pool

Technology : infrared

Other characteristics : real-time, with integrated camera

Reviews

There are no reviews yet.