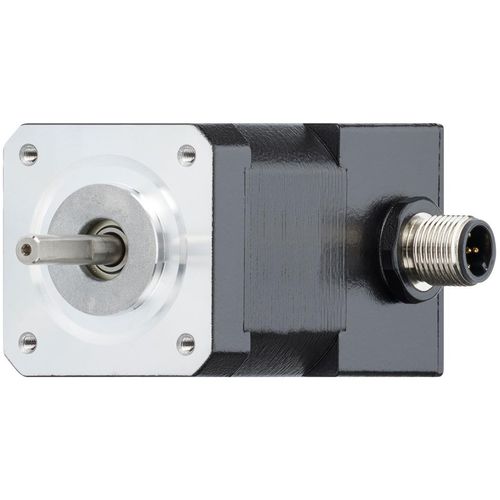

This little motor has impressive torque and high RPMs. Reliable operation with quick movements of low loads.

Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, their precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection.

Motors with stranded wires are the least expensive and the most common stepper motors. The connecting wires for this type exit from the housing and will be connected with a JST connector. They are usually installed in machines and equipment that have an additional housing or are used in clean environments.

When combined with the appropriate gearbox, drylin® linear axes with the new BLDC motors achieve higher speed and greater torque. Energy is used more efficiently, as a result of which EC/BLDC motors are more durable and have a longer service life. Due to the fact that carbon brushes are not used, brushless motors are almost completely wear-resistant, generate less heat and enable longer, uninterrupted operation. The EC/BLDC motors have the same connections as NEMA 17/23/24/34 stepper motors.

• Brushless motors enable higher speed and greater torque

• Longer operating time and service life

• Virtually wear-free

• Less heat generated

• for all drylin® linear modules and axes with NEMA17/23/24/34 hole pattern

AC/DC : DC

Type : stepper

Voltage : 60 V

Protection class : IP65, IP68, IP40

Configuration : NEMA 17, NEMA 23, NEMA 34

Torque : Max.:

Current : Max.:

Operating temperature : Max.:

Reviews

There are no reviews yet.