Due to varying gap dimensions level measuring at removable tanks is often challenging. EBE sensors + motion has developed an elegant solution to offset the manufacturing and mounting tolerances of the plastic parts used.

The company EBE sensors + motion offers a new sensor technology optimized especially for issues with plastic removable tanks. The manufacturing of plastic tanks and unit frames entails manufacturing tolerances that result in varying gap dimensions between tank wall and unit frame. Varying wall thicknesses, thermal deformation of the plastic parts over their lifetime or tanks not properly inserted can significantly influence the measuring distances. If the variations exceed two millimetres the level measurement by conventional capacitive sensors often presents a problem.

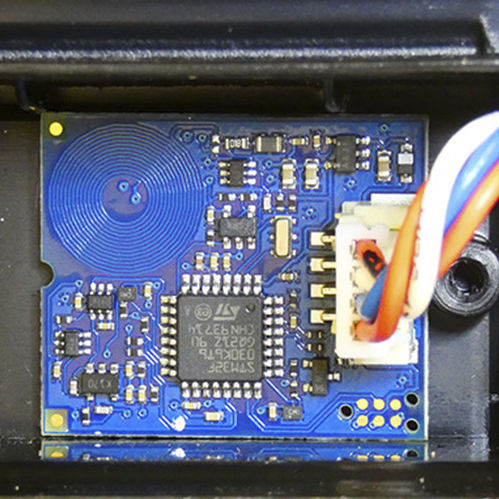

This effect is compensated by the new combi sensor from EBE. The capacitive level sensor with electrode structure and µ-controller is also equipped with an inductive proximity sensor. The filling level is measured from outside through the tank wall, the tank cavity and the unit frame. By means of the proximity sensor the actual distance between the sensor surface and the tank surface is measured. A small piece of aluminium is totally suffices as counterpart for the induTEC®-sensor. Based on the individual air gap the parameters for the capacitive sensor are thus tracked in real time. The sensors are available both as filling level or limit value switch or as continuously measuring sensor.

Technology : capacitive

Medium : for liquids

Interface : not specified

Applications : for storage tanks

Reviews

There are no reviews yet.