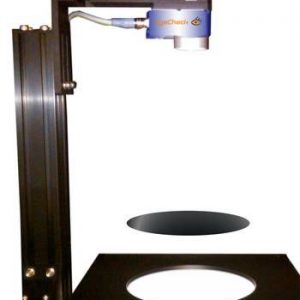

EBERHARD INSPECTION SYSTEM EIS 3D

The next generation in connector inspection:

Our inspection system EIS 3D is equipped with high-end vision inspection technology. It makes connector testing more effective and precise. The modular Design enables the integration of EIS 3D in a fully-automatic production line.

FEATURES

– 3D line scan camera

– Contactless, in-line measuring of the true position and pin height, without prolonging the cycle time of the Eberhard assembly systems

– High image acquisition speed, at a line frequency of 21,2 kHz

– Precise 3D measurements with the unique combination of line scan camera technology and rapid 3D stereo calculation

– 3D line scan camera technology reduces shadowing to a minimum and enables the detection of the finest pins, even in deep connector cavities

– Intuitive visualization of production data and easy process analysis based on a variety of evaluation screens, within a newly designed user interface

TECHNICAL DATA

– Optical resolution: 15 µm/Pixel

– Field of view (scan width): 40 mm

– Max. measurable connector length: 300 mm

– Line frequency: 21,2 kHz

– Max. acquisition speed: 300 mm/s

MEASUREMENT RELIABILITY AT NANOPINS

– Standard deviation, pin height: 8µm

– Repeatability cg pin height (tolerance ± 0,2mm): ≥1,67

– Standard deviation, true position: 5µm

– Repeatability of true position: cg ≥ 2,67, tolerance ± 0,2mm

Technology : camera, 3D, scanning, non-contact

Operational mode : automatic

Type : measurement

Other characteristics : in-line, non-contact

Reviews

There are no reviews yet.