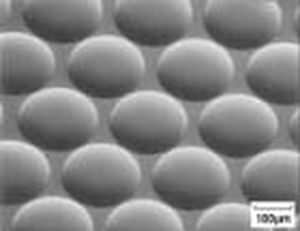

Teledyne Scientific & Imaging fabricates and manufactures Silicon microlenses using advanced processing techniques. We use Reflow and Grayscale fabrication methods to achieve high quality, cost efficient microlenses. Reflow involves patterning polymeric materials on substrates and then melting the polymer to form ideal spherical surfaces. Lenses produced by this method have a wide range of design parameters and numerical apertures, and aspheric design over many conic values.

Grayscale photolithography is used in fabricating asymmetric micro-optic structures. This technique enables complex optical structures to be fabricated including full fill-factor lens arrays, kinoform and Fresnel lens patterns, concave and off-axis lenses, and diffraction gratings.

Refractive and diffractive microlens arrays and optical components

Variety of materials including Silicon Quartz (fused Silica), many III-V or II-VI semiconductor and polymeric materials

Reflow and Grayscale fabrication

ISO 9001 certified manufacturing operation at RSC including a variety of plasma etch/mill tools

Class 100 cleanroom facilities, diagnostic instruments, including phase-shifting interferometric surface profilers, AFM, SEM, and TEM instruments

Expert staff with knowledge of materials, optical design, modeling, and manufacture process engineering

Material : BK7

Optical characteristics : ultraviolet

Other characteristics : microscopic

Reviews

There are no reviews yet.