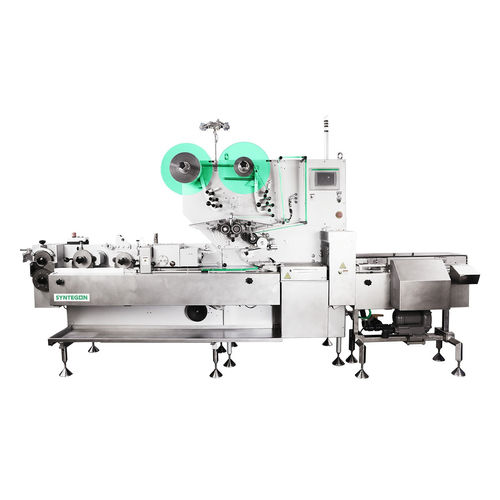

Cutting and packaging of soft and hard sugar masses, chewing candy and chewing gum masses. Resettable to plate feeding for formed candy (optional).

Method of operation:

• Drive of the forming roller pairs is performed via a servo-controlled separate servo-motor for infinitely variable adjustment of the product lengths and for uniform rope conveyance.

• Wear-resistant materials and coatings for all rope-guiding components.

• Rope monitoring between the forming rollers and rope cutter.

• Oscillating cutter for a straight, smooth cut – integrated stripper on the cutter.

• Upon cutting, transfer of the product is effected into the short duplex feed chain with a sufficient dwell time for shape stabilization prior to transfer into the packaging material tube.

• Constant lubrication of the cutter drive, splash lubrication – no oil circulation.

• High cutter tool life and antiadhesion properties due to the special coating.

• Integrated components for optional water cooling of the rope cutter.

Benefits:

• Easy size changes due to infinitely variable adjustment of product lengths, heights and pack lengths, as well as rapidly changeable parts for changing the product and pack widths.

• Large size ranges covered. High output without changing the crosssealing rollers or driver chain.

• Solid product-contact components for constant production conditions after size changes.

• Possibility of on-site combination of the rope feed with our infeed system for preformed candy.

• Automatic reel changing at end of reel and with web tear monitoring.

• Easy operator control and size management via touch screen.

Operational mode : automatic

Type : horizontal

Domain : for the food industry

Throughput : 1,600 p/min

Reviews

There are no reviews yet.