Customized labelling machines Energy 300 for horizontal application of self-adhesive labels on multi-packages

The challenge: Implementing a suitable labelling system to reduce the use of plastic packaging on multi-packs of wet wipes

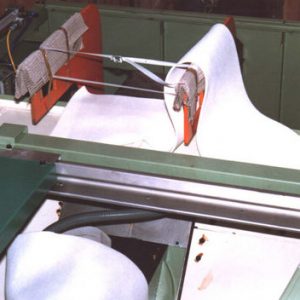

“A.P.I.’s need was to optimise the demand for a particular packaging system”, says Vice President Pierbattista Maglio. The company was looking for a tailor-made system for the labelling of multi-pack wet wipes to be integrated into the packaging line commissioned by a manufacturer of personal care products. The aim was to find a solution that could avoid the use of secondary plastic packaging to assemble individual packs of wipes. This particularity determined the need to completely revolutionise the product labelling logic. It was necessary to switch from a standard vertical application, to a horizontal application in order to be integrated into the line designed by A.P.I for horizontal product loading and handling.

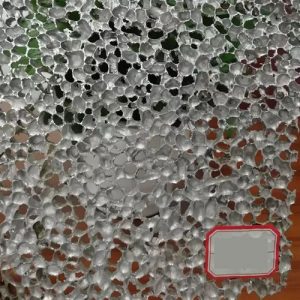

To achieve the required result, Etipack designed two tailor-made Energy labelers which, positioned at the end of the line in two stations – above and below the conveyor belt – carry out simultaneous product labeling. As a batch passes over the conveyor belt, the labelers apply two labels, one on the top and one on the bottom of the packs, allowing 5 packs of wet wipes to be assembled into a single multi-pack. The solution therefore completely eliminates the need for additional packaging. The system allows the use of large labels up to 200 mm long and 298 mm wide and achieves a distribution speed of up to 20 m/min.

Operational mode : automatic

Label application : top, bottom

Type : for self-adhesive labels

Other characteristics : horizontal

Reviews

There are no reviews yet.