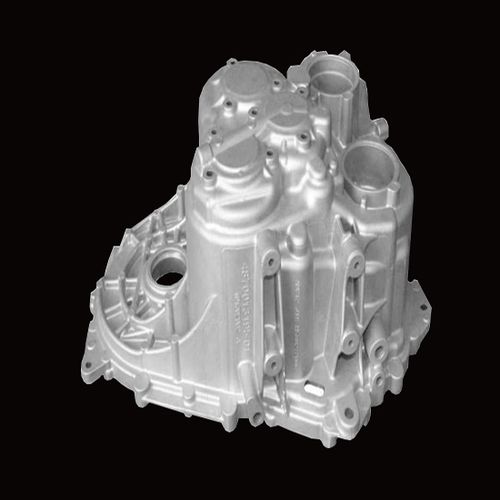

►With 15 sets cold-chamber die casting machine from 250-800 ton; 1 set hot-chamber die-casting machines 160 ton.

►The annual output of all kinds of aluminium alloy, zinc alloy, magnesium alloy die casting parts is more than 5000 tons; The maximum annual capacity is more than 8000 tons

►Up to 1000 products, auto parts, telecommunication, security, Lighting, Home appliance are the main products.

►Minimum single piece 0.05 KG, maximum single piece 25 KG.

►Each equipment is basically equipped with automatic soup, automatic spraying, automatic pick-up function;

►Some large equipment also equipped with automatic deburring, orthopaedic functions, the degree of automation in the peer in the leading level.

►The advanced vacuum die casting technology and die temperature control technology are mastered to ensure the quality stability and high production efficiency in the production process

The process of Finishing an order :

►Inquiry

Customer send the demands and requirements details ,including the part data( 2d/3d drawings with format of IGES, DXF, DWG, STP, PRT, )

►Quote

Single parts we quote it in one day while project parts in 3-5 days based on the technical demands and function details . The quote will including the cost way (EX-WORK/FOB/CIF/DDU/DDP etc) and delivery time . It also show the payment term ( 50% for the deposit ,the rest 50% before the shipping or 100% payment )

► Order released

For the new customer , they may make sample order before the batch one .

Whether the value low or high we will keep top quality and service . We are reliant partner for you .

Material : aluminum, zinc

Applications : automotive

Reviews

There are no reviews yet.