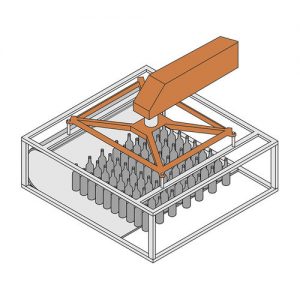

Gripper with compensation unit, pneumatic

For part handling in the machine tool.

Application:

The gripper achieves a fully automatic workpiece change during the machining process on a machine tool. It is changed from the tool magazine of the milling machine and enables workpiece handling between the part storage and the clamping device. It is actuated by means of compressed air, which is routed through the machine spindle. The gripper closes pneumatically and opening takes place by means of spring force.

The integrated spring-loaded CX counterbalance function protects the tool, machine spindle and workpiece, and compensates for tolerances and unevenness.

Note:

– Max. permitted speed: 20 [rpm]

– Suitable for Weldon seat and hydraulic expansion chucks

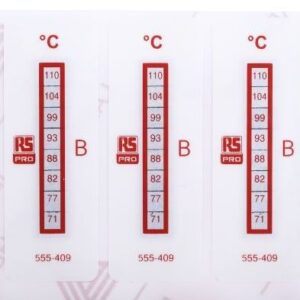

– Designed for ambient temperatures from 0°C to 60°C

– Transportation of workpieces up to a max. of 8 kg

– The standard supply includes three replacement seals

– Available in two designs for workpiece sizes up to a max. of 50 mm or 70 mm

Advantage:

– The counterbalance function (Z: 5 mm, C: +/- 3°) ensures that all components are optimally protected and tolerances and unevenness are compensated

– The gripping force can easily be adjusted using the pressure control valve and thereby adapted to the relevant requirements of the workpieces

– Easily exchangeable gripper inserts for handling various workpiece geometrics

– Easy implementation of unmanned shifts, which means greater machine utilisation and more flexibility

– Tremendous reduction of set-up times for smaller to medium-sizes batches

Operation : pneumatic

Type : parallel

Number of jaws : 2-jaw

Reviews

There are no reviews yet.