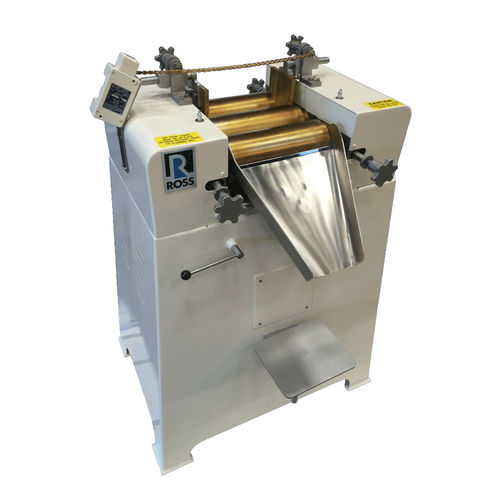

The material to be milled is placed between the feed and center rolls. Each adjacent roll rotates at progressively higher speeds. For example; the feed roll may rotate at 30 rpm, the center roll at 90 rpm and the apron roll at 270 rpm. Material is transferred from the center roll to the apron roll by adhesion. The dispersion is achieved by the shear forces generated between the adjacent rolls. The milled material is removed from the apron roll by a knife that runs against the roll.

STANDARD FEATURES:

• 1/2 HP through 15 HP

• Driven by a TEFC 230/460V, 3 Ph, 60 Hz, inverter-duty motor

• 21 /2” x 5” model: stainless steel type 440C hardened precision ground rolls with adjustable Tefl on endplates

• Production models: carbon steel type 52100 hardened precision ground rolls with adjustable bronze endplates

• Stainless steel type 304 apron

• Rolls are cored to allow water cooling or heating

• All non-stainless steel external surfaces coated with a white two-part epoxy paint

• Safety trip switch across the top of the mill

Technology : roller

Orientation : horizontal

Product application : miscellaneous waste

Other characteristics : for the pharmaceutical industry, laboratory, stainless steel, hydraulic

Rotational speed : 270 rpm, 348 rpm, 360 rpm, 428 rpm (1,696 rad.min-1)

Reviews

There are no reviews yet.