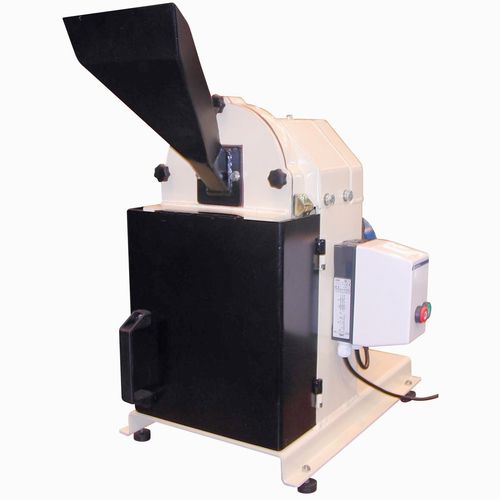

This compact, sturdy pulveriser has been designed and developed in South Africa for the general grinding requirements of a typical industrial laboratory. The South African coal industry makes use of these mills.

For normal use, the units are supplied with a cloth collection bag, which also serves as an effective air filter. A specification feature is long-life roller and ball bearings, enclosed and lubricated for trouble-free service over extended periods of use.

A turbo rotor can be fitted to the existing shaft. When new the use of the turbo rotor can provide a product size of 97% -212 micron. Turbo rotors can be refurbished and dynamically balanced if they become worn.

The 200 Lab Mill is used for crushing:

Bricks

Chemicals

Coal

Concrete

Grain

Ores & Minerals

Soil

Spices

and many more materials in the medium hard range.

Once the material is fed into the feed chute, it quickly flows into the mill grinding chamber where it is pulverised against the chamber lining by impact with the fast moving hardened hammers.

Once the particles reach the required size they are discharged through interchangeable screens into the collection bag or receptacle.

Maximum capacity and milling performance is dependent on the material being processed, size of the screen and the hammer configuration.

Technology : cross beater

Orientation : horizontal

Product application : grain, for coal grinding

Other characteristics : compact, laboratory

Rotational speed : 6,000 rpm (37,699 rad.min-1)

Motor power : 2 kW (3 hp)

Machine weight : 68 kg (150 lb)

Reviews

There are no reviews yet.