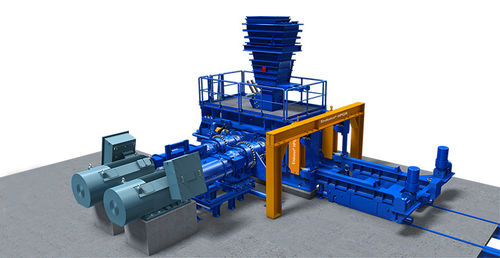

Enduron® high pressure grinding rolls (HPGR) set the benchmark for energy efficient grinding and use dynamic skewing to provide best-in-class wear life for mining applications.

Overview

With low energy consumption, low maintenance requirements and high availability, Enduron® high pressure grinding rolls are a proven way to improve the efficiency of minerals and aggregate grinding circuits.

Our innovative design allows our Enduron® HPGR to maximise crushing pressure while allowing oversized and tramp materials to pass without incident through dynamic skewing. This is only possible with the unique bearing design of our Enduron® HPGR, which prevent bearing failure and enable the rollers to be quickly exchanged within a 24-hour shutdown.

Key features:

Energy reductions of up to 40% when compared to traditional grinding circuits

Superior tyre lifetime with premium tungsten carbide studs designed to promote a robust autogenous wear layer

Optimised diameter to width ratio which produces more fines than the competition

Skewing allows for passage of tramp or oversize material while maintaining best possible grinding conditions

Unique bearing assembly allows for dynamic skewing without the risk of bearing failure

Spring loaded lateral walls prevent particle leakage during skewing

Quick roller exchange without disassembly of feed chute/hopper

Skewing is a vital feature for high pressure grinding rolls as feed variance, segregation and the presence of tramp materials are inevitable in real world grinding circuits and will lead to uneven grinding and selective wear of the tyres.

Technology : hydraulic

Orientation : horizontal

Product application : for ore

Other characteristics : compact, high-pressure

Output : 7,500 t/h (4,593 lb/s)

Reviews

There are no reviews yet.