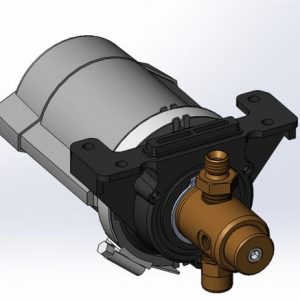

ViscoTec dosing and filling pump type RD-hygienic for food and cosmetics is a volumetric conveying pump based on the endless piston principle. Suitable for discontinuous or continuous pulsation-free metering of viscous, shear sensitive and high-filled material.

Special and highly accurate dosing applications can be achieved with the help of the high-quality ViscoTec dispensers. For example, ViscoTec systems are used in the bakery and confectionary business for the decoration of cookies, cakes, etc. Typically, icing or fudges are dosed but also sweet filling like vanilla or chocolate pastes.

Your advantages:

– Dosing units with specific filling nozzles depending on each individual application

– Dispensing within automated lines

– Low to high viscosity fluids which could contain abrasive, shear-sensitive particles or fillers

– Hot and cold filling process

– Perfect results at CIP/SIP (Cleaning/Sterilisation in Place) cleaning: it can be integrated in an automatic flushing system

– Options possible

The dosing unit for filling machines can be used as feeding pump in subsequent processes: As conveying pump from A to B, to be used in barrel emptying systems, in the food and cosmetics sector and for hot filling and cold filling.

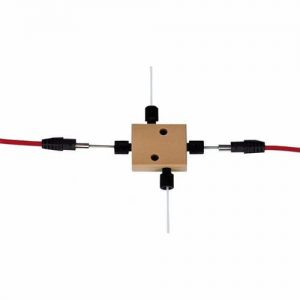

Accessories:

– hopper with 10 l or 50 l

– manifolds with air bleed valve

– food or pharmaceutical hoses

– pressure sensors for pump protection and control

Fluid : for dairy products, for cream, whey

Operation : electrically-actuated

Priming : self-priming

Domain : for the food industry, laboratory, for the pharmaceutical industry, for hygienic applications, for the cosmetics industry, medical

Applications : suction, sampling, trial, level control, dual dispensing, proportional dosage, control, control, volumetric dispensing, for automatic machines, handling, mixing, cleaning, process, purge, metering, for precision applications, recirculation, for industrial applications, booster, for sterile applications, for harsh environments, test, filling, discharge, high-temperature, medium-pressure, rinsing, drum, for emulsions, IBC, drain, service, feed, distribution, injection

Material : EPDM, stainless steel, metal, PTFE

Fluid specification : flavouring, dye, for abrasive fluids, for aggressive media, for corrosive fluids, for hazardous fluids, for high-purity fluids, for low-viscosity fluids, for high-viscosity fluids, for toxic fluids, for viscous fluids, for solids-laden fluids

Protection level : hazardous-duty, abrasion-resistant, chemical-resistant

Other characteristics : compact, horizontal mount, single-stage, two-stage, with mechanical seals, heavy-duty, low-flow, high-efficiency, low-noise, modular, high-flow, variable-speed, medium-flow, skid-mounted, with electronic control, integrated, base-mounted, adjustable-flow, automatic, high-reliability, rugged, transportable, variable-flow, low-capacity, axial-flow, heavy-duty, with speed controller, stand-alone, flange, mechanical, waterproof, with security, with variable-speed controller, electronic regulation, corrosion-proof, programmable, custom, custom, for packaging machines, constant-pressure, double-jacketed, high-power, high-performance, small-size, with pressure controller, with frequency converter, sensor, floor-mounted, medium-sized, double-acting, with seal, continuous-flow, ball bearing, direct-drive, OEM, electromechanical, vertical, single-acting, cased, servo-driven, adjustable, rugged, low-pressure

Flow : Min.:

Pressure : Min.:

Reviews

There are no reviews yet.