THE INTELLIGENT PRACTICE LAB SOLUTION

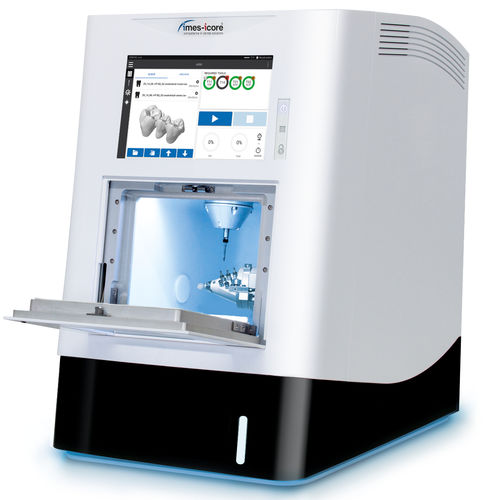

The new CORiTEC one® machine is a perfect choice for processing all common designed CAD/CAM blocks. With the new extremely stable axis kinematics, the machine is also capable to mill prefabricated abutments.

The high-quality cast aluminum construction ensures maximum stability with a minimum footprint. An integrated powerful PC along with 10‘1” HD touch screen display supports a comfortable and ergonomic operation. A single block holder with six tool positions and smart tool replacement function guarantee an economical, safe and fast machining process with the highest quality. CORiTEC one is ideally suited every dental offices, practice laboratory and clinic in combination with all open scanners. As a supplemental system for the specialized processing of glass ceramic, zirconia, composite and premilled abutment the CORiTEC one leaves nothing to be desired either for clinics, laboratories or milling centers.

Highlights of the CORiTEC one & one+

MONO-BLOCK CAST BODY

novel closed

mono-block cast body for

stability and precision

INTEGRATED WATER SUPPLY AND FILTRATION

SELF-SUFFICIENT OPERATION

No external Compressed air needed

SCANNER COMPATIBLE

with all open scanners (STL)

HIGH-PERFORMANCE SPINDLE

high end spindle

for milling and grinding

up to 100.000 rpm

ADAPTER VARIETY

Adapter for all common blocks and

pre-milled abutments

Number of axes : 5-axis

Spindle orientation : vertical

Other characteristics : high-performance, CAD/CAM, dental, for composites, glass

Power : 1 kW (1 hp)

Reviews

There are no reviews yet.