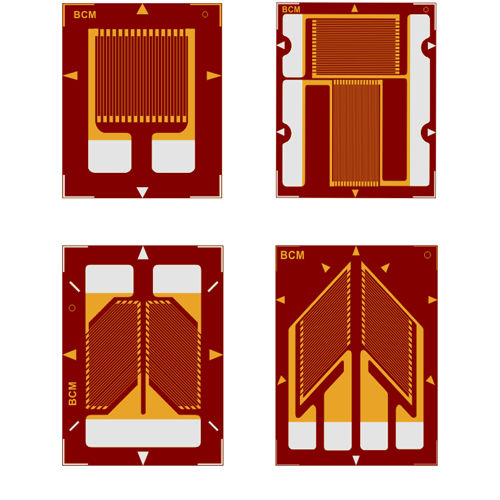

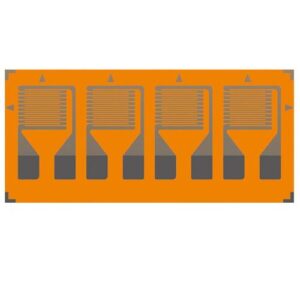

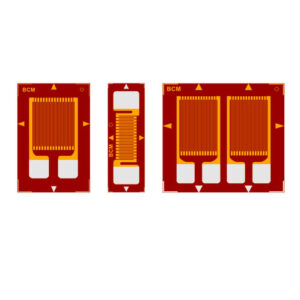

For purpose of load cell manufacturing, the most three commonly-used strain gauges (SG) are the linear SG (AA-pattern) for bending beam, the 90°-rosette SG (BB-pattern) for compression beam (column), and the dual shear SG (HA-pattern) for shear-beam load cells.

All of these three categories of SGs from BCM SENSOR are both temperature-compensated and creep-compensated, and they are suitable for manufacturing of load cells of a combined error of 0.01%fs.

The temperature-compensation of load cells can be facilitated by those strain gauges with an either STC code of 11 for both mild steel and martensitic stainless steel of ~11ppm/°C, STC code of 16 for both austenitic stainless steel and copper of ~16ppm/°C, or STC code of 23 for aluminum alloy of ~23ppm/°C.

For creep compensation, there are 18 creep codes available for selection: “N10, N9, N8, …, O, …, P5, P6, P7″. The “N10” represents the most negative creep code, while the “P7″ is the most positive one. The “O” stands for a moderate creep. For a specific strain gauge, its available creep codes are listed in the selection chart of datasheet. For a customized creep code, one can consult BCM SENSOR.

The strain gauge with effective modulus compensation (EMC) is available only for the karma gauge which is mostly used for low-cost force sensor manufacturing.

For details, please refer to strain gauge datasheets on BCM SENSOR website.

Technology : resistive, resistance

Geometry : linear, single-grid, biaxial, dual-grid

Other characteristics : for stress analysis, for force measurement, high-accuracy, flexible, encapsulated, for steel, surface, half-bridge, with compensation resistors, high-performance

Resistance : Min.:

Gauge factor (k) : Min.:

Reviews

There are no reviews yet.